Hydropower is the safest and cleanest source of power generated in the world today

For over 100 years all hydropower facilities use the free flow weight of water flowing down stream in order to spin Impact turbines which in turn generate hydropower.

Until now…

![]()

Our Technology

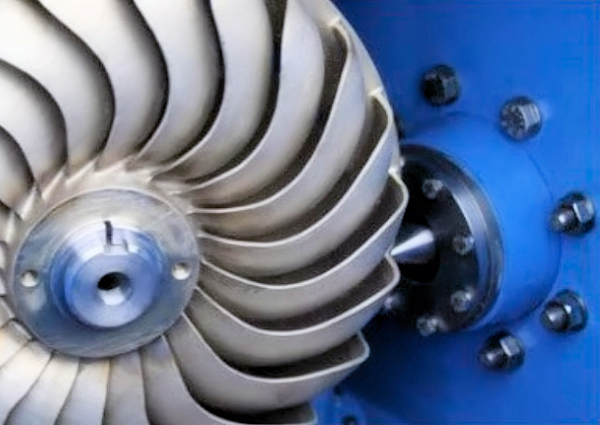

We accomplish increased Pelton turbine power production through increased Jet Projectile velocities from our patented Hammer1 Gun Valve. The Hammer1 Gun Valve is the device used to start and stop the fluid movement that creates the additional jet velocity, thus additional kinetic energy.

Increased Efficiencies

Hydro Power Technologies Inc. has developed a system to increase the power output of a pelton Turbine hydro generation system. The first generation of products from HPT system known as “Hammer1“, utilizes hydraulic water phenomena to produce rapid fire, high speed, long water projectiles that have a velocity 1.25 to 1.30 times greater velocity than the traditional “Free Flow” turbines in operation to-day. The additional velocity increases the rotational torque of the pelton turbine runner thus increasing the power generation.

Technology Applications

Our innovative approach has applications in the retrofitting of existing hydropower systems, and new Hydropower System installations resulting in increased energy generation.

Energy Storage and Recovery Systems are an excellent application also.

Value Proposition

Generating more power and utilizing less water resources alleviates the concern of climate change and socio economic factors by providing scalable product offerings that satisfy the underlying requirement for customers seeking renewable, reliable and cost effective energy solutions.

![]()

Technology Overview

Hammer1 – Simplified Principle of Operation

- the water is fed to the penstock from the upper reservoir

- driven by a servo motor, the actuator closes the Hammer1 Gun Valve achieving the desired transient hydraulic effect

- the shock wave is sent back up the penstock and returns

- the Hammer1 Gun Valve opens and the shock wave rushes through, forming a high velocity projectile of water which exits the valve and impacts the runner of the pelton turbine

- it is this increased rotational torque that creates additional power as compared to a free-flow fed pelton turbine

- the opening and closing of the valve happens many times per second and is controlled by the HammerNET software and Hammer1 Gun actuator

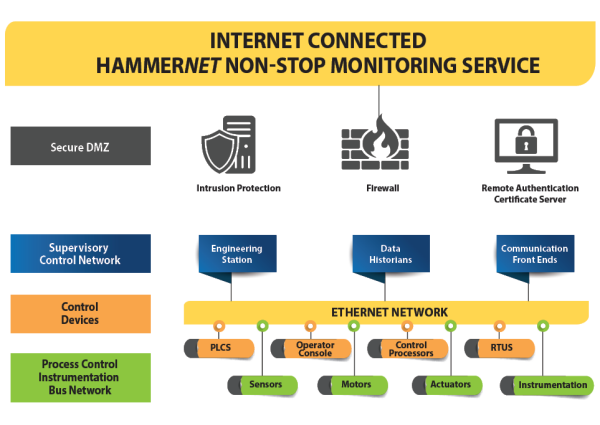

HammerNET – Operating Environment

HammerNET is the Ethernet IP network and controller platform that provides real-time process control management for all system components.

Throughout and integral to the Hammer1 system are a series of controllers that HammerNET continuously polls to ensure the operation and continuity of the hydro generation systems. In conjunction with local operator consoles and Hammer1 instrumentation panels, HammerNET ensures the operational integrity and power generation process.

Adhering to the principles of the ICS410 ICS/SCADA security essentials, network hardened Secure Zones and dual factor authentication, enable remote support and maintenance of all system components, to and from the Internet connected HPT HammerNET Monitoring Centre.

The support and services of the HPT monitoring center are included as part of a comprehensive customer support and maintenance program for all HPT technology offerings.

NEXT: